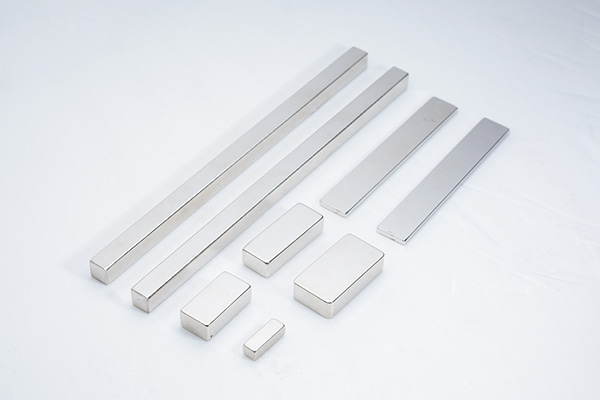

Square magnet

Origin: China

Model:

You can through the customer service hotline, consulting product information

Description

Sintered NdFeB permanent magnet material has excellent magnetic performance, widely used in electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields, the more common permanent magnet motor, speakers, magnetic separator, computer disk drive, magnetic resonance imaging equipment and instruments, etc. Welcome to provide your drawings and specifications to manufacture custom magnets

Magnetic performance table

| Grade | Remanence(Br) | Coercivity(bHc) | Intrinic Coercivity | Max Energy Product | Working Temperature Tw ℃ | ||||

| (iHc) | (BH)max | ||||||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ||

| N35 | 1.18-1.23 | 11.8-12.3 | ≥860 | ≥10.8 | ≥955 | ≥12 | 263-287 | 33-36 | ≤80 |

| N38 | 1.22-1.28 | 12.2-12.8 | ≥860 | ≥10.8 | ≥955 | ≥12 | 287-310 | 36-39 | ≤80 |

| N40 | 1.26-1.31 | 12.6-13.1 | ≥876 | ≥11.0 | ≥955 | ≥12 | 302-326 | 38-41 | ≤80 |

| N42 | 1.28-1.34 | 12.8-13.4 | ≥876 | ≥11.0 | ≥955 | ≥12 | 318-342 | 40-43 | ≤80 |

| N45 | 1.32-1.37 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | ≤80 |

| N48 | 1.36-1.42 | 13.6-14.2 | ≥876 | ≥11.0 | ≥955 | ≥12 | 358-390 | 45-48 | ≤80 |

| N50 | 1.39-1.45 | 13.9-14.5 | ≥876 | ≥11.0 | ≥955 | ≥12 | 374-406 | 47-51 | ≤80 |

| N52 | 1.42-1.48 | 14.2-14.8 | ≥796 | ≥10.0 | ≥876 | ≥11 | 390-422 | 49-53 | ≤80 |

| N54 | 1.45-1.51 | 14.5-15.1 | ≥756 | ≥9.5 | ≥876 | ≥11 | 400-440 | 51-55 | ≤80 |

| N35M | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11 | ≥1114 | ≥14 | 263-287 | 33-36 | ≤100 |

| N38M | 1.22-1.28 | 12.2-12.8 | ≥876 | ≥11 | ≥1114 | ≥14 | 287-310 | 36-39 | ≤100 |

| N40M | 1.26-1.31 | 12.6-13.1 | ≥876 | ≥11 | ≥1114 | ≥14 | 302-326 | 38-41 | ≤100 |

| N42M | 1.28-1.34 | 12.8-13.4 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 318-342 | 40-43 | ≤100 |

| N45M | 1.34-1.39 | 13.4-13.9 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 342-366 | 43-46 | ≤100 |

| N48M | 1.36-1.42 | 13.6-14.2 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 366-390 | 46-49 | ≤100 |

| N50M | 1.39-1.45 | 13.9-14.5 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 384-408 | 48-51 | ≤100 |

| N35H | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11 | ≥1353 | ≥17 | 263-287 | 33-36 | ≤120 |

| N38H | 1.22-1.28 | 12.2-12.8 | ≥876 | ≥11 | ≥1353 | ≥17 | 287-310 | 36-39 | ≤120 |

| N40H | 1.26-1.31 | 12.6-13.1 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | ≤120 |

| N42H | 1.28-1.34 | 12.8-13.4 | ≥955 | ≥12 | ≥1353 | ≥17 | 318-342 | 40-43 | ≤120 |

| N45H | 1.33-1.39 | 13.3-13.9 | ≥955 | ≥12 | ≥1353 | ≥17 | 342-366 | 43-46 | ≤120 |

| N48H | 1.36-1.42 | 13.6-14.2 | ≥955 | ≥12 | ≥1353 | ≥17 | 366-390 | 46-49 | ≤120 |

| N50H | 1.39-1.45 | 13.9-14.5 | ≥955 | ≥12 | ≥1274 | ≥16 | 384-408 | 48-51 | ≤120 |

| N33SH | 1.14-1.19 | 11.4-11.9 | ≥836 | ≥10.5 | ≥1592 | ≥20 | 247-270 | 31-34 | ≤150 |

| N35SH | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | ≤150 |

| N38SH | 1.22-1.28 | 12.2-12.8 | ≥876 | ≥11 | ≥1592 | ≥20 | 287-310 | 36-39 | ≤150 |

| N40SH | 1.26-1.30 | 12.6-13.0 | ≥923 | ≥11.6 | ≥1592 | ≥20 | 302-326 | 38-41 | ≤150 |

| N42SH | 1.28-1.34 | 12.8-13.4 | ≥955 | ≥12 | ≥1592 | ≥20 | 318-342 | 40-43 | ≤150 |

| N45SH | 1.33-1.39 | 13.3-13.9 | ≥955 | ≥12 | ≥1592 | ≥20 | 342-366 | 43-46 | ≤150 |

| N48SH | 1.36-1.42 | 13.6-14.2 | ≥955 | ≥12 | ≥1592 | ≥20 | 366-390 | 46-49 | ≤150 |

| N28UH | 1.03-1.09 | 10.3-10.9 | ≥740 | ≥9.30 | ≥1990 | ≥25 | 207-231 | 26-29 | ≤180 |

| N30UH | 1.09-1.14 | 10.9-11.4 | ≥796 | ≥10 | ≥1990 | ≥25 | 223-247 | 28-31 | ≤180 |

| N33UH | 1.13-1.19 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1990 | ≥25 | 247-263 | 31-33 | ≤180 |

| N35UH | 1.18-1.22 | 11.8-12.2 | ≥876 | ≥11 | ≥1990 | ≥25 | 263-287 | 33-36 | ≤180 |

| N38UH | 1.22-1.27 | 12.2-12.7 | ≥876 | ≥11 | ≥1990 | ≥25 | 287-310 | 36-39 | ≤180 |

| N40UH | 1.26-1.30 | 12.6-13.0 | ≥923 | ≥11.6 | ≥1990 | ≥25 | 302-326 | 38-41 | ≤180 |

| N42UH | 1.28-1.34 | 12.8-13.4 | ≥955 | ≥12 | ≥1990 | ≥25 | 318-342 | 40-43 | ≤180 |

| N28EH | 1.03-1.09 | 10.3-10.9 | ≥740 | ≥9.30 | ≥2388 | ≥30 | 207-231 | 26-29 | ≤200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | ≥796 | ≥10.0 | ≥2388 | ≥30 | 223-247 | 28-31 | ≤200 |

| N33EH | 1.13-1.19 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 247-263 | 31-33 | ≤200 |

| N35EH | 1.18-1.22 | 11.8-12.2 | ≥876 | ≥11 | ≥2388 | ≥30 | 263-287 | 33-36 | ≤200 |

| N38EH | 1.22-1.27 | 12.2-12.7 | ≥876 | ≥11 | ≥2388 | ≥30 | 287-310 | 36-39 | ≤200 |

| N40EH | 1.26-1.30 | 12.6-13.0 | ≥923 | ≥11.6 | ≥2388 | ≥30 | 302-326 | 38-41 | ≤200 |

| N28AH | 1.03-1.09 | 10.3-10.9 | ≥740 | ≥9.30 | ≥2786 | ≥35 | 207-231 | 26-29 | ≤220 |

| N30AH | 1.08-1.13 | 10.8-11.3 | ≥796 | ≥10.0 | ≥2786 | ≥35 | 223-247 | 28-31 | ≤220 |

| N33AH | 1.13-1.17 | 11.3-11.7 | ≥836 | ≥10.5 | ≥2786 | ≥35 | 247-263 | 31-33 | ≤220 |

| N35AH | 1.18-1.23 | 11.8-12.3 | ≥876 | ≥11.0 | ≥2786 | ≥35 | 263-287 | 33-36 | ≤220 |

size specification

| Block products | range of sizes(mm) | size(mm) | Maximum processing accuracy | ||||

|---|---|---|---|---|---|---|---|

| L | W | T | dimensional tolerance | depth of parallelism | verticality | ||

| 1<L<=300 | 1<L<=100 | 1<L<60 |

L<=10 10<L<=60 60<L<=100 100<L<=300 |

±0.03 ±0.05 ±0.1 ±0.15 |

0.05 0.1 0.2 0.2 |

0.1 0.1 0.3 0.5 |

|

| Circle chip products | range of sizes(mm) | size(mm) | Maximum processing accuracy | |||

|---|---|---|---|---|---|---|

| D | T | dimensional tolerance | depth of parallelism | verticality | ||

| 2<OD<=300 | 1<T<60 |

OD<=10 10<OD<=60 60<OD<=100 100<OD<=300 |

±0.03 ±0.05 ±0.1 ±0.15 |

0.05 0.1 0.2 0.2 |

0.1 0.1 0.3 0.5 |

|

| arc | range of sizes(mm) | size(mm) | Maximum processing accuracy | |||||

|---|---|---|---|---|---|---|---|---|

| OD | H | W | T | dimensional tolerance | depth of parallelism | verticality | ||

| / | 2<H<=250 | 2<H<=100 | 1<T<=60 |

H<=10 10<H<=60 60<OD/ID<=100 100<OD/ID<=300 |

±0.03 ±0.05 ±0.1 ±0.15 |

0.05 0.1 0.2 0.2 |

0.1 0.1 0.3 0.5 |

|

surface protection

| Plated layer type | pigment | Plated thickness(μm) | SST(h) |

| Trivalent chromium blue white zinc | White blue | 4—10 | 12-24 |

| Trivalent chromium color zinc | undertint | 4—10 | >24 |

| phosphorization | gray | / | 4—8 |

| Nickel copper nickel | silvery | 10—30 | >24 |

| Black nickel | Metal black | 10—30 | >24 |

| Nickel + tin | silver | 10—30 | >48 |

| Nickel + silver | silver | 10—30 | >48 |

| Nickel + gold | golden | 10—30 | >48 |

| epoxy black | black | 10—30 | >24 |

| epoxy white | white | 10—30 | >48 |

| Nickel copper + epoxy black | black | 20—40 | >48 |

| Nickel + epoxy black | black | 20—40 | >48 |

Focus on

Focus on